Types of Aerators Used in Wastewater Treatment Plants

Aeration is a vital process in wastewater treatment plants and is often described as the “lungs” of biological treatment systems. It involves the controlled introduction of oxygen into wastewater to support aerobic microorganisms responsible for breaking down organic pollutants. In addition to oxygen transfer, aeration also ensures proper mixing, prevents solids settlement, and maintains uniform process conditions.

Aerators used in wastewater treatment plants play a major role in determining treatment efficiency, energy consumption, and overall plant performance. Since aeration systems typically account for a significant portion of operational energy usage, selecting the right aeration technology is critical for long-term and reliable operation.

This article explains the main types of aerators used in wastewater treatment plants, their working principles, and their practical applications.

Why Aeration Is Important in Wastewater Treatment

Biological treatment processes rely on microorganisms that require a continuous supply of dissolved oxygen. An effective aeration system ensures that:

Adequate oxygen is available for biological activity

- Wastewater and biomass remain uniformly mixed

- Dead zones and sludge accumulation are avoided

- Stable treatment performance and effluent quality are maintained

Improper aeration can result in reduced biological efficiency, odor issues, and operational instability.

Major Types of Aerators Used in Wastewater Treatment Plants

Aeration technologies are generally classified based on how oxygen is introduced into the wastewater and how mixing is achieved within the treatment basin.

1. Surface Aerators

Surface aerators introduce oxygen by agitating the water surface, allowing atmospheric oxygen to dissolve into the wastewater. These aerators are commonly installed in open basins, lagoons, and oxidation ditches.

Key characteristics:

- Simple installation and operation

- Provide surface-level aeration and mixing

- Suitable for shallow to moderate tank depth

Typical applications:

- Aeration ponds and lagoons

- Equalization tanks

- Oxidation ditches

Surface aerators are often selected where basin geometry is open, and ease of maintenance is an important consideration.

2. Diffused Aeration Systems

Diffused aeration systems use external blowers to supply air through a network of pipelines connected to submerged diffusers. As air bubbles rise through the wastewater, oxygen transfers into the liquid.

Types of diffused aeration:

- Fine bubble diffusers: High oxygen transfer efficiency, commonly used in deeper tanks

- Coarse bubble diffusers: Strong mixing capability and resistance to clogging, suitable for high-solids applications

Key characteristics:

- Widely used in large treatment facilities

- Oxygen transfer depends on bubble size and tank depth

- Requires blower systems and periodic maintenance

Diffused aeration is preferred where precise oxygen control and process optimization are required.

3. Jet Aerators

Jet aerators use a recirculation pump to force wastewater through a nozzle, creating a high-velocity jet that entrains air and disperses it into the tank.

Key characteristics:

- Strong mixing and circulation

- Suitable for deeper tanks

- Effective for variable or high-strength wastewater

Jet aerators are often applied in industrial wastewater treatment and specialized process tanks.

4. Aspirating Aerators

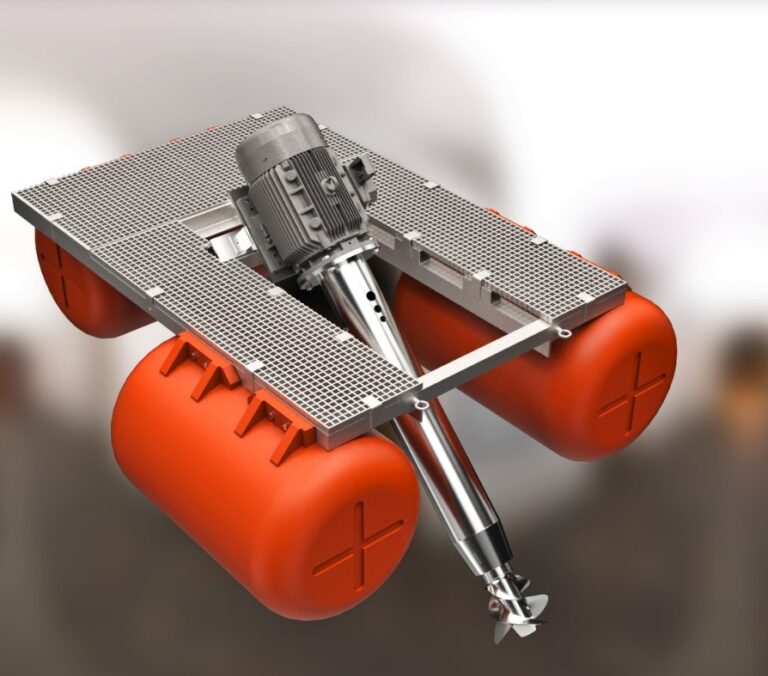

Aspirating aerators are self-aspirating systems that draw atmospheric air directly into the wastewater using a rotating impeller. These aerators do not require external blowers, making them mechanically simple and operationally flexible.

Among the aerators used in wastewater treatment plants, aspirating aerators are valued for combining aeration and mixing in a single unit. One example of this technology is the CyclOxy Aspirator, which is engineered to deliver consistent air induction and uniform circulation within biological treatment zones.

Working principle:

- A rotating impeller creates a low-pressure zone

- Atmospheric air is drawn through a hollow shaft

- Air is dispersed into fine bubbles within the wastewater

- Horizontal circulation ensures even oxygen distribution

Key advantages:

- No separate air blower or air piping system

- Reduced system complexity and maintenance

- Strong mixing across the tank volume

CyclOxy is designed to address common operational challenges associated with aeration by maintaining stable oxygen transfer and preventing solids settlement. Such aspirating aerators are commonly used in aeration tanks, equalization basins, and biological treatment processes where wastewater characteristics may vary.

Factors to Consider When Selecting an Aerator

The selection of aerators used in wastewater treatment plants should be based on a balanced evaluation of technical and operational factors, including:

- Tank depth and basin geometry

- Wastewater characteristics and organic loading

- Required oxygen transfer and mixing intensity

- Energy consumption and operational efficiency

- Maintenance requirements and lifecycle costs

Choosing the right aeration technology helps ensure long-term reliability and efficient plant performance.

Conclusion

Aeration is a fundamental component of wastewater treatment, directly influencing biological efficiency, energy usage, and overall process stability. Understanding the different aerators used in wastewater treatment plants—including surface aerators, diffused aeration systems, jet aerators, and aspirating aerators—enables informed decision-making during system design and operation.

By selecting aeration equipment that aligns with process requirements and operational conditions, treatment facilities can achieve consistent effluent quality while optimizing performance and sustainability.